Hatch 100% into quality DOC

What it is

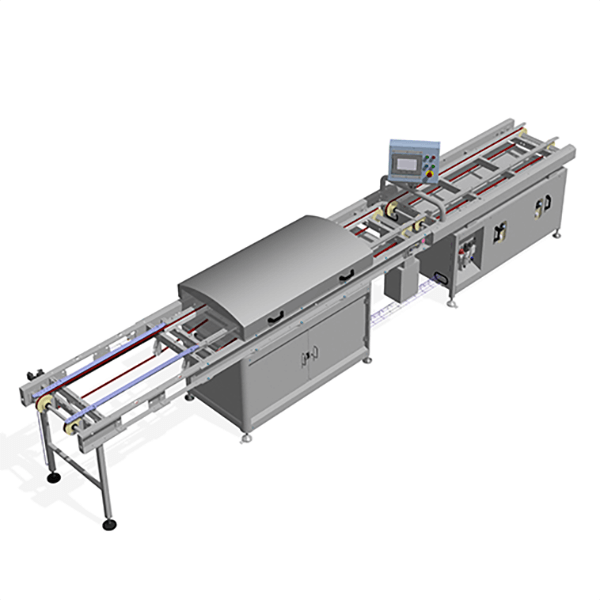

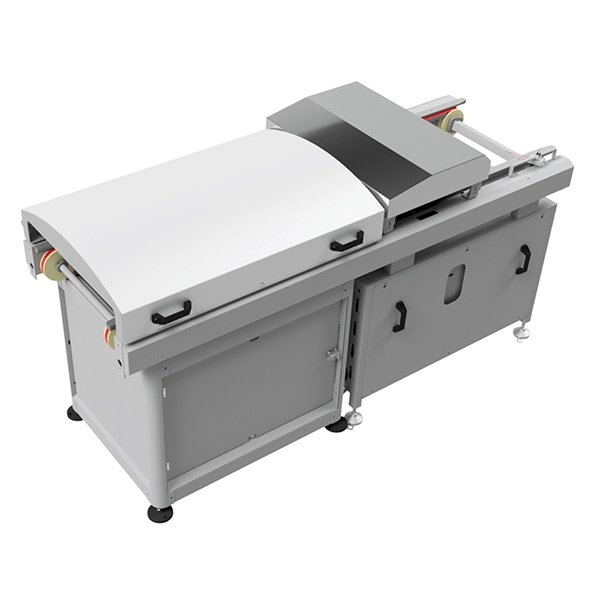

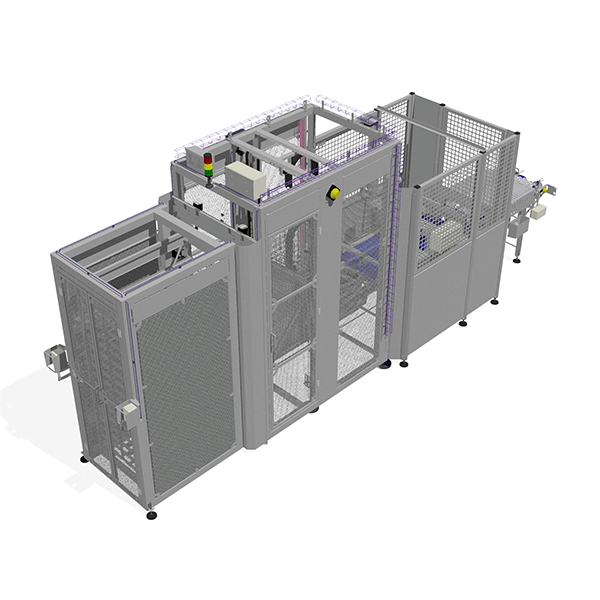

The innovative Ovosense®, identifies and marks the upside-down eggs. Ovosense® improves the hatchery output by offering fast, simple and effective egg setting analysis.

How it works

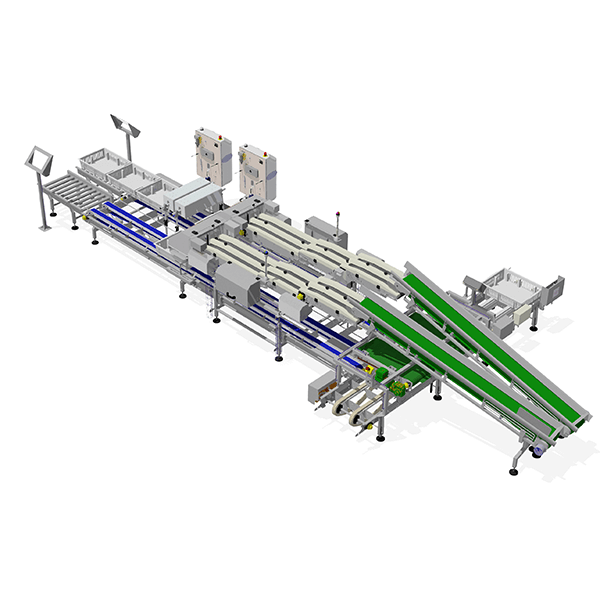

- Eggs coming from the breeder farms are normally transferred into hatchery trays.

- During this step, eggs can be wrongly positioned. These are called upside-down eggs.

- Via innovative sensors, Ovosense® detects eggs that are located upside down and marks them.

- Then the marked eggs can be manually set properly.

What is an upside-down egg?

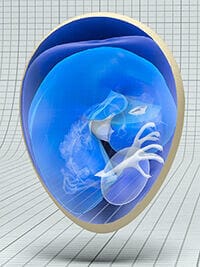

PROPER SETTING

Embryo's head is towards air chamber in the blunt end. The embryo will use the air chamber to breath at hatch.

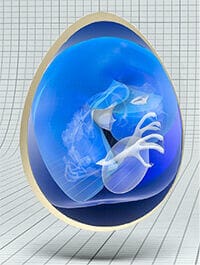

UPSIDE-DOWN EGG

Embryo's head is located away from the air chamber. The embryo cannot reach the air chamber to breath at hatch.

Equipment features

- Non Operator Dependant: all the eggs are well set

- High Speed Solution: reach up to 90,000 eggs analysed/hour

- Massive ROI, specially with young flocks and round-eggs breeds

- High accuracy: detection accuracy is reaching 99.9%

Why is it so important?

Embryos from upside-down eggs will not hatch regularly. If they do, they are normally discarded as cull chicks.

On average, 1% to 3% of eggs delivered to the hatchery would be upside down depending on the automation level. Identification of upside-down eggs before incubation gives a chance for 100% of the fertile eggs to produce a good day-old chick.

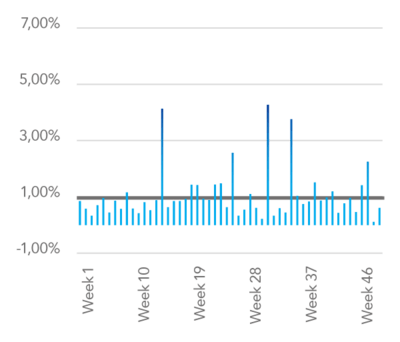

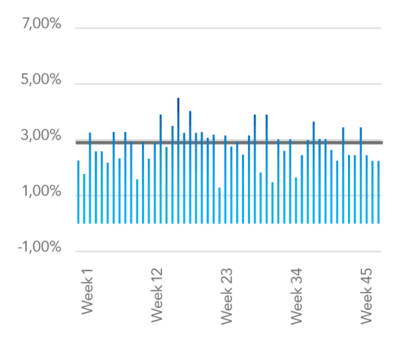

Case A: Yearly data from a non-integrated hatchery, shows an average of 1.04% upside-down eggs.

Case B: Yearly data from an integrated hatchery, shown an average of 2.82% upside own eggs.

- 1% upside down eggs represents around 489,000 day-old-chicks.