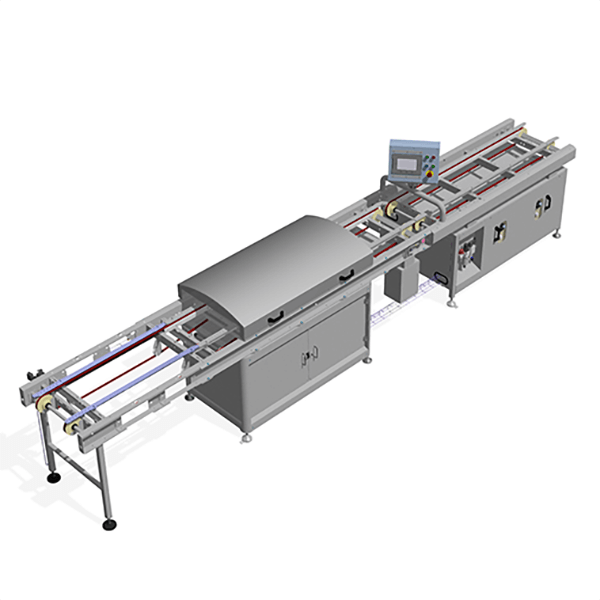

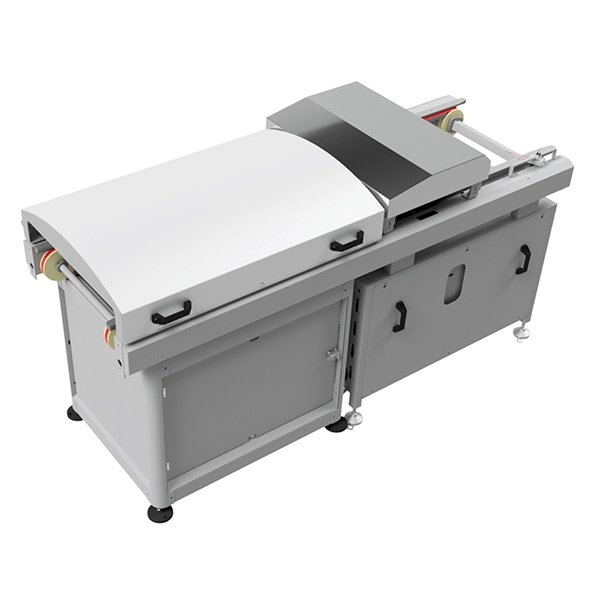

Tray Unloader

What it is

- The setter trays unloader is the solution for quick, smooth unloading of setter trays from trolley to processing line.

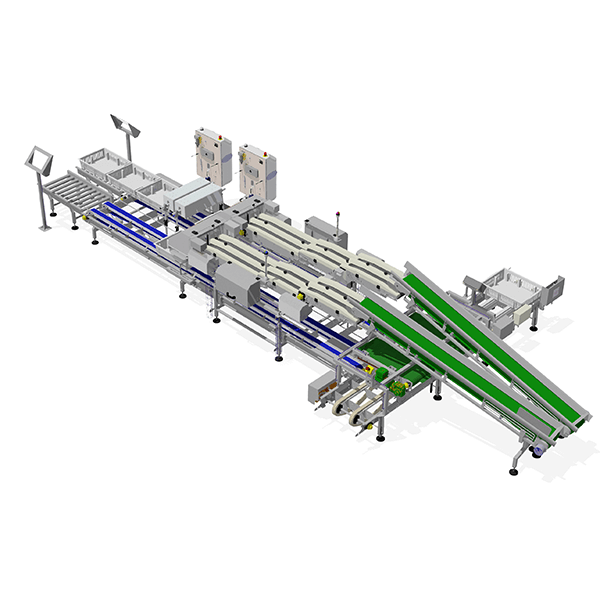

- With a smooth motion, the transfer process imposes minimum stress for the chicks, which is fundamental. We can supply robotic solutions to reduce the risk of injuries due to the shock with fully controlled acceleration for all the movements.

Tray Unloader: Optimizing Setter Tray Handling

The tray unloader is an indispensable piece of equipment designed to streamline the process of unloading setter trays from trolleys onto the processing line. At the hatchery the efficiency and gentle handling of eggs are a must. The tray unloader is a solution to respond to these concerns effectively. Especially in a market context where production volume is increasing, and human resources availability is limited.

These solutions not only facilitate the handling of increased production efficiently but also help compensate for the shortage in labor resources. In this context, embracing high-speed solutions becomes not just an option but a strategic necessity for hatcheries willing to optimize productivity and cross through the challenges posed by limited resources.

Efficiency in Motion

One of the features of the tray unloader is its ability to perform this delicate operation with efficiency and precision. By transferring setter trays from trolley to processing line, it minimizes disruption in the workflow. This is crucial in hatchery operations where time-sensitive processes are a constant consideration.

Key advantages of the key unloader:

Enhanced Efficiency: The tray unloader significantly enhances the efficiency of the unloading process, reducing downtime and optimizing the overall productivity of the hatchery.

Adaptability: Tray unloaders are adaptable to the needs of each hatchery size, accommodating variations in tray sizes and production volumes.

Maintenance and Reliability: This equipment is built for durability, requiring minimal maintenance and ensuring consistent, reliable performance.

Operator Safety: By automating the tray unloading process, operator safety is improved as there is a reduced need for manual handling, particularly of heavy trays.

The tray unloader is an essential component in an automatized hatchery, combining efficiency, precision, and care to ensure the smooth transition of egg from trolley to processing line.