Designed to be safe

What it is

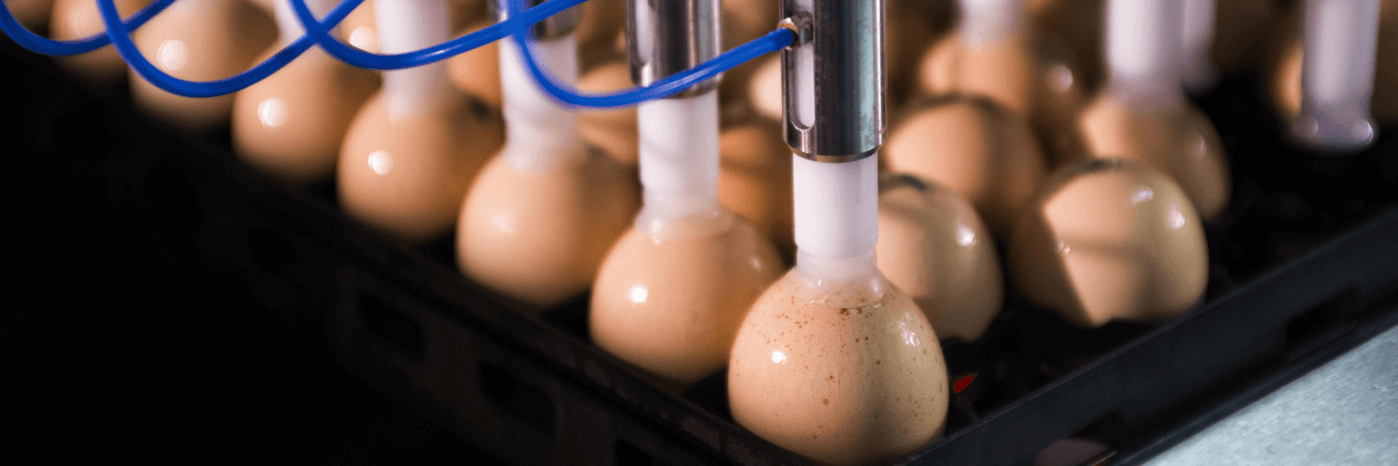

For modern hatcheries, the Egginject® full line allows safe In-Ovo Vaccination thanks to its Dual Pressure Injection System.

How it works

Only live embryos are transferred to hatch baskets, dead and rotten eggs remain untouched in the tray

1st Step:

High pressure is used to perforate the eggshell. As the pressure is applied only on a very small area of contact.

2nd Step:

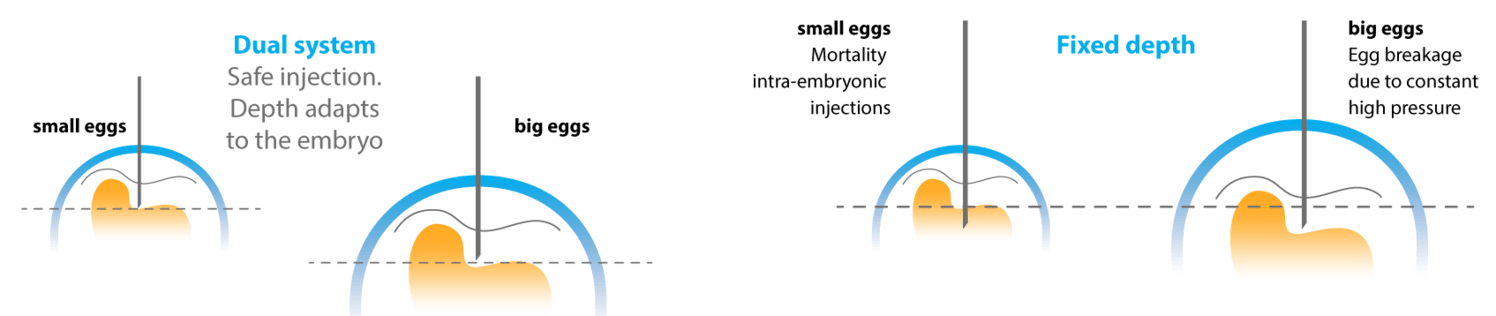

Once the needle is inside the egg, the system changes to low pressure. Each needle automatically adapts the injection depth according to the size and position of the embryo.

Adaptable depth versus fix depth

Equipment features

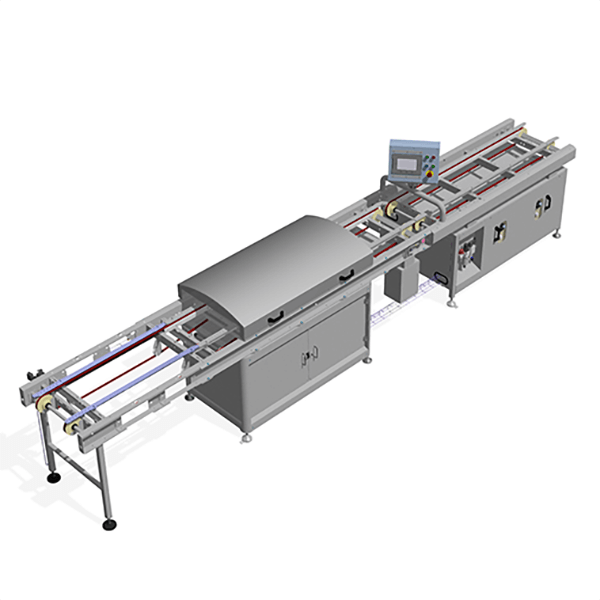

- Speed up to 60,000 eggs/hour

- Adaptable to all types of incubation trays

- Easy to use: simple and operator friendly

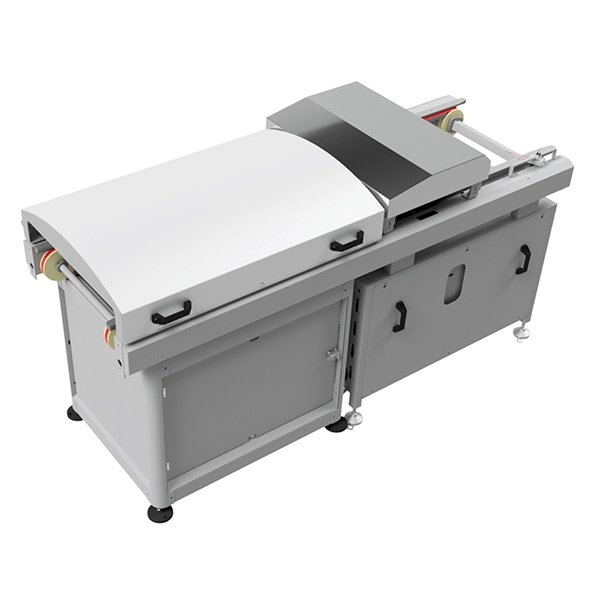

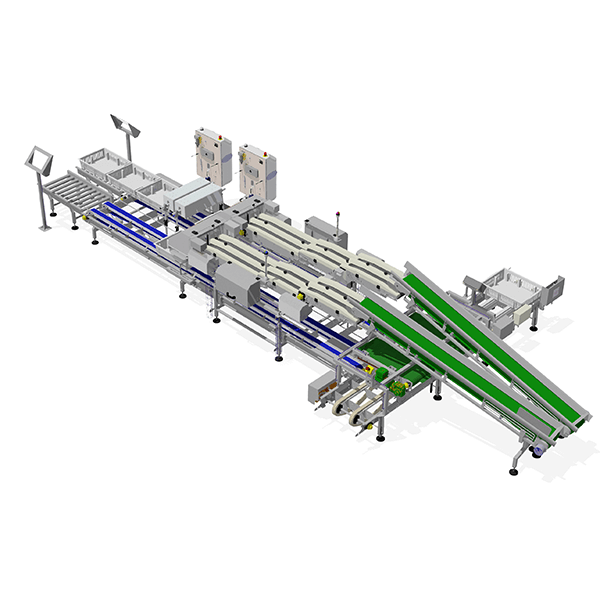

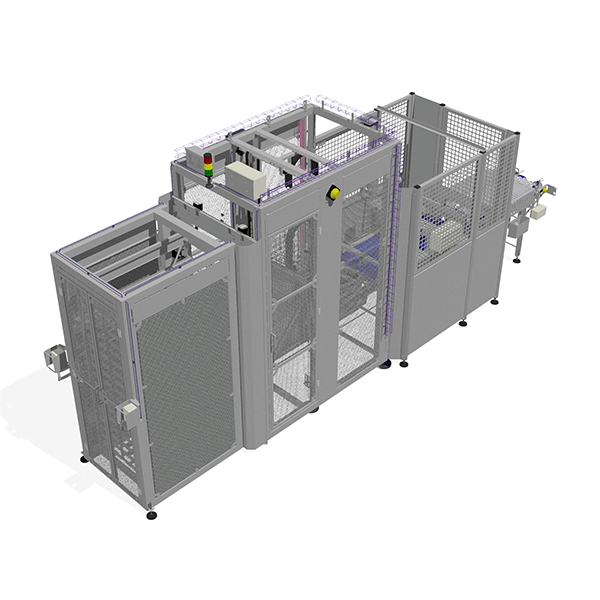

- Stand alone or fully integrated in the hatchery automation line

- No vaccine waste while priming

- Negligible egg breakage

- Minimized hatchability impact

Why it is so important?

In-ovo vaccination represents major benefits for day-old chick production:

- Safe, constant and accurate method of vaccine application

- Significant labour cost reduction vs sub-cutaneous or field vaccination

- No post-vaccination reaction

- Early access to food and water. Day-old-chicks are not stressed after hatch

- Better development of the immune system at hatch.

- Improvement of the chick quality of your flocks

Learn more about in-ovo vaccination here.

Need more information?

Egginject®: Revolutionizing In-Ovo Vaccination for Modern Hatcheries

Discover the advanced Egginject® system, designed to ensure safe and efficient in-ovo vaccination for hatcheries. Utilizing a patented dual pressure injection technology, Egginject® guarantees precise vaccine delivery by adapting the injection depth to the size and position of each embryo. This innovative approach minimizes egg breakage and maximizes hatchability, making it the preferred choice for hatcheries worldwide.

Key Features of Egginject®:

- Dual Pressure Injection System: High pressure perforates the eggshell, while low pressure ensures accurate vaccine delivery. This dual mechanism is crucial for maintaining the integrity of the egg while ensuring the vaccine reaches the embryo effectively.

- Adaptable Injection Depth: The system automatically adjusts the injection depth based on the embryo's position and egg size. This adaptability is essential for ensuring that each egg receives the correct dosage, regardless of variations in egg size or embryo development stage.

- High Throughput: Egginject® is capable of processing up to 60,000 eggs per hour, making it one of the most efficient systems available. This high throughput is vital for large-scale hatcheries looking to optimize their operations and reduce manual labor.

- Versatile Integration: The Egginject® system can be used as a standalone unit or integrated into existing hatchery automation lines. This versatility allows hatcheries to seamlessly incorporate Egginject® into their current processes without significant modifications.

- Operator-Friendly: Designed with ease of use in mind, Egginject® reduces labor costs and improves efficiency. Its user-friendly interface ensures that operators can quickly learn and manage the system, minimizing downtime and training costs.

- Minimal Vaccine Waste: The system ensures that no vaccine is wasted during priming, which is both cost-effective and environmentally friendly. This feature is particularly important for hatcheries looking to reduce their operational costs and environmental impact.

- Enhanced Chick Quality: By promoting better immune system development and reducing post-vaccination stress, Egginject® contributes to the overall health and quality of the chicks. Healthier chicks lead to better growth rates and lower mortality, which are critical factors for hatchery success.

Benefits of In-Ovo Vaccination with Egginject®:

- Safety and Accuracy: Egginject® provides a consistent and reliable method of vaccine application, ensuring that each embryo receives the correct dosage. This precision is crucial for maintaining the health and viability of the chicks.

- Cost Efficiency: In-ovo vaccination with Egginject® reduces labor costs compared to traditional subcutaneous or field vaccination methods. This cost efficiency is essential for hatcheries looking to optimize their budgets and improve profitability.

- Improved Chick Welfare: Early access to food and water leads to healthier and less stressed chicks. By vaccinating embryos before they hatch, Egginject® ensures that chicks are better prepared for the challenges of early life.

- Optimal Immune Development: Ensuring better immune system development at hatch improves overall flock quality. Chicks vaccinated in-ovo have a stronger start, which translates to better performance throughout their lives.

- Reduced Risk of Disease Transmission: In-ovo vaccination minimizes the risk of disease transmission compared to traditional methods. This reduction in disease risk is vital for maintaining the health and productivity of the flock.

- Environmental Benefits: By reducing vaccine waste and improving efficiency, Egginject® contributes to more sustainable hatchery practices. This environmental benefit is increasingly important as hatcheries look to reduce their ecological footprint.

Choose Egginject® for a cutting-edge solution to in-ovo vaccination, enhancing the productivity and quality of your hatchery operations. With its advanced technology and proven benefits, Egginject® is the ideal choice for modern hatcheries aiming to improve efficiency, reduce costs, and promote chick welfare. Learn more about Egginject® and its benefits for modern hatcheries.